|

Deformational |

Other areas of DC application

![]()

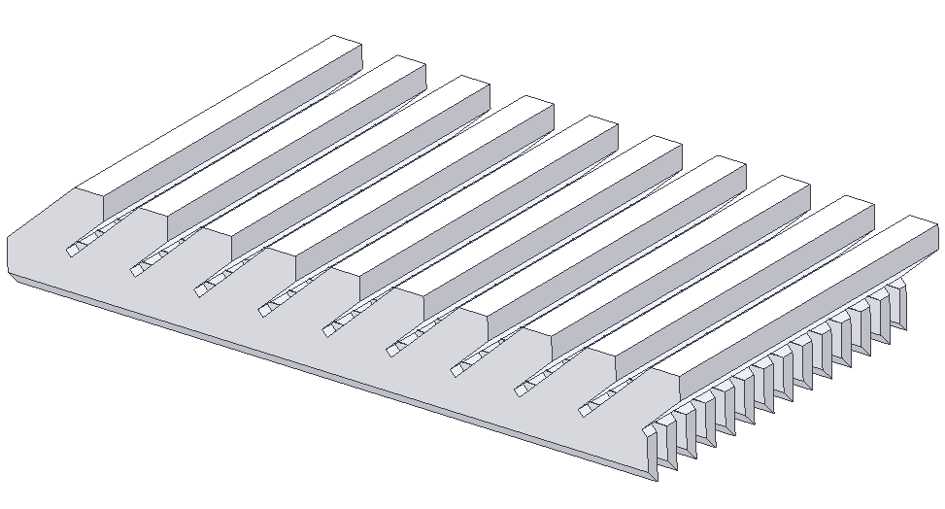

1 - Threading and V-shaped grooves on ductile materials

- one tool pass

- almost no waste

- no need for lubricoolant

- high-grade finish

- ability to get ridge height more that initial tube wall thickness

|

|

|

Fig. 1.1 - Thread G1/2" on copper tube |

Fig. 1.2 - Aluminum V-shaped grooves. Pitch 60 microns |

2 - Fine finish cutting using DC tool of high-ductile (copper, lead, pure aluminum etc.) and high-elastic (rubber, polyurethane etc.) materials or non-rigid parts.

- high-grade finish

- no barbs

- no need for lubricoolant

- minimum cutting forces, temperature, unrelieved stress and cold hardening

3 - Permeable plates for a System of Transpiration Cooling with flow angularity.

|

|

Article "The Hydraulic Characteristics of Porous Materials for a System of Transpiration Cooling"

4 - Strain hardening.

|

|

Creating a finning with zero-width of interfinl gap provides increasing of surface hardness of 1.5 ... 2.0 times with a depth of units of millimeters. Unlike other types of strain hardening it is no exponential decrease in hardness over the thickness of the hardened layer. Can be used for the parts from not quenching materials or large-dimensioned steel parts.

5 - Subsurfaces cavities for lubricants with capillary exit to a surface for hardened bearings and parts of friction.

|